The quiet strength of modern commerce lives inside warehouses. From last-mile delivery hubs to massive distribution centers, these buildings keep economies moving even when customers never see what’s inside. That’s why warehouse construction isn’t just another real estate project—it’s a strategic investment with long-term operational consequences.

In reality, a warehouse that’s poorly planned can bleed money through inefficiency, while a smartly built one can boost productivity for decades. Decisions made early—location, layout, materials—tend to echo long after construction crews pack up.

If you’re exploring warehouse construction for logistics, manufacturing, or storage, this guide breaks the process down in plain language. We’ll talk real numbers, practical design choices, and lessons learned from the field, not theory.

However, beyond concrete and steel, there’s also compliance, safety, scalability, and future growth to consider. Let’s walk through it all like two professionals at the same table.

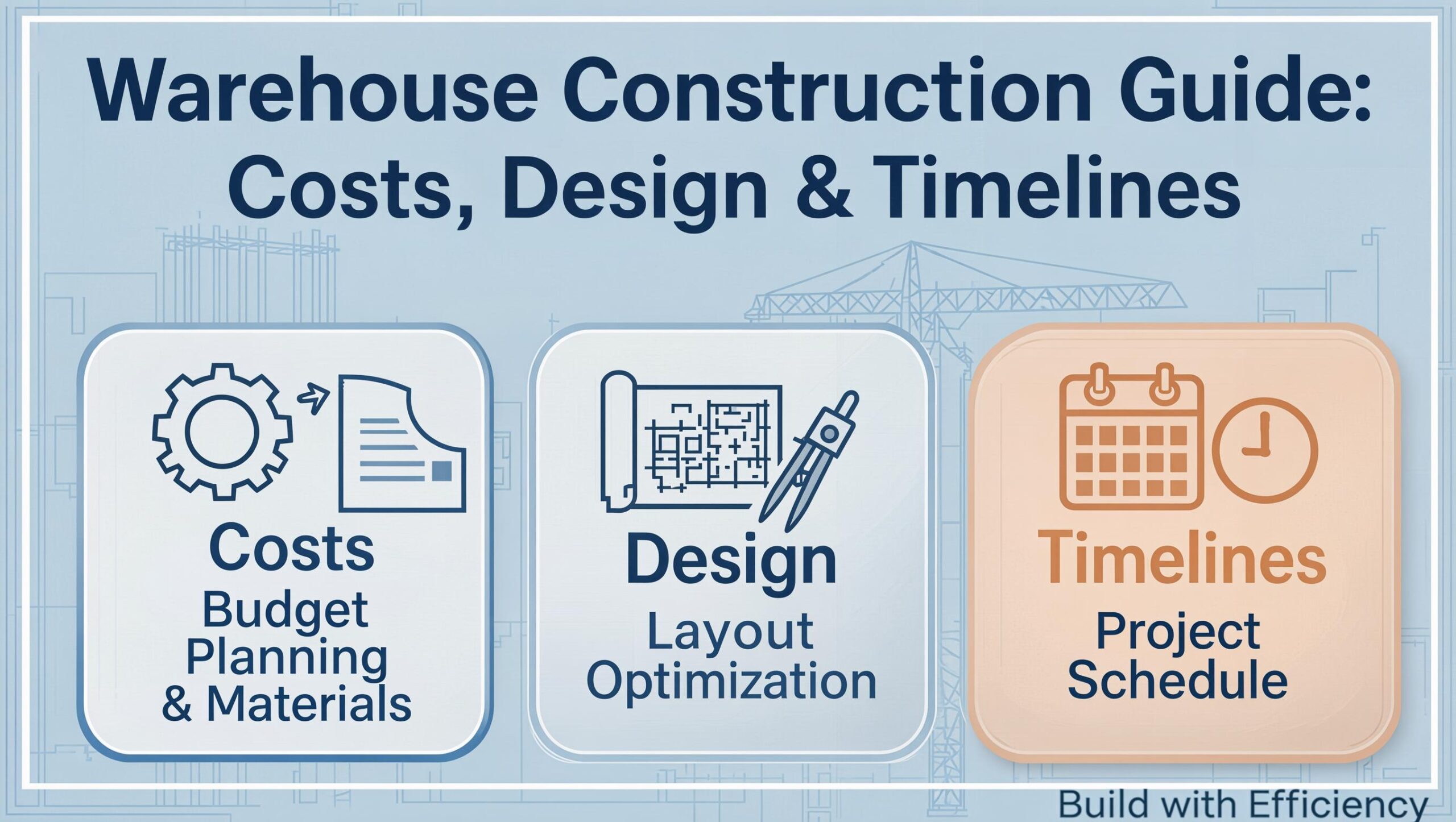

[Infographic: Warehouse construction process from planning to completion]

What Is Warehouse Construction?

Warehouse construction refers to the planning, design, and building of industrial facilities used for storage, distribution, or manufacturing support. Unlike residential or commercial projects, these buildings prioritize functionality, load capacity, and logistics efficiency over aesthetics.

That said, modern warehouse construction blends engineering, architecture, and supply chain strategy. A well-built warehouse supports faster order fulfillment, safer working conditions, and lower long-term operating costs.

In most projects, the process includes land evaluation, zoning approval, architectural design, structural engineering, material selection, and phased construction.

Why Warehouse Construction Matters in Today’s Economy

The Rise of E-Commerce and Logistics

Online shopping changed everything. As same-day and next-day delivery expectations rise, warehouse construction has become a backbone of modern retail. Distribution centers are now positioned closer to urban populations to reduce delivery times.

On the other hand, industrial zones near highways, ports, and railways remain critical for regional and national supply chains.

Long-Term Cost Efficiency

Cutting corners during construction often leads to higher operational expenses later. Poor insulation, inefficient layouts, or limited expansion capacity can quietly drain budgets. Thoughtful warehouse construction focuses on lifecycle costs, not just upfront spending.

Key Types of Warehouse Construction

Steel Frame Warehouses

Steel structures dominate modern industrial construction due to durability and speed. Steel warehouses are:

-

Faster to erect

-

Resistant to fire and pests

-

Easier to expand vertically or horizontally

However, steel prices fluctuate, which can impact budgets unexpectedly.

Concrete Warehouses

Concrete construction offers superior load-bearing capacity and temperature stability. These facilities are common in cold storage and heavy manufacturing environments. That said, concrete builds often take longer and require higher upfront investment.

Pre-Engineered Buildings (PEBs)

Pre-engineered warehouse construction uses factory-fabricated components assembled on-site. This method reduces waste, shortens timelines, and improves cost predictability.

Site Selection and Land Considerations

Choosing the wrong site can sink a warehouse project before construction begins. Location decisions should consider:

-

Proximity to highways, ports, and suppliers

-

Soil stability and drainage

-

Zoning and environmental regulations

-

Utility access (electricity, water, gas, data)

In reality, cheaper land far from transport routes often costs more over time due to logistics inefficiencies.

Warehouse Construction Costs Explained

Average Cost Breakdown

Warehouse construction costs vary widely based on region, size, and specifications. On average:

| Cost Component | Percentage of Total Cost |

|---|---|

| Land & Permits | 10–20% |

| Materials | 35–45% |

| Labor | 20–30% |

| Mechanical & Electrical | 10–15% |

| Contingency | 5–10% |

For basic facilities, costs may start around $50–$80 per square foot, while advanced logistics hubs can exceed $150 per square foot.

Factors That Increase Costs

-

High-clearance ceilings

-

Specialized flooring for heavy loads

-

Automation systems

-

Climate control or cold storage requirements

That said, these features often pay for themselves through operational efficiency.

Timeline: How Long Does Warehouse Construction Take?

Warehouse construction timelines depend on complexity. A simplified breakdown looks like this:

-

Planning & permits: 2–4 months

-

Design & engineering: 1–3 months

-

Site preparation: 1 month

-

Construction phase: 4–9 months

In total, most projects complete within 8–18 months. Delays often stem from permitting issues or material shortages rather than construction itself.

Warehouse Design Principles That Actually Work

Layout and Workflow Optimization

A warehouse should reduce unnecessary movement. Smart layouts place high-turnover items near loading docks and minimize cross-traffic. In reality, even small layout changes can shave minutes off every order cycle.

Ceiling Height and Vertical Space

Modern warehouse construction favors vertical storage. Higher ceilings allow more racking capacity without expanding the footprint, especially valuable where land prices are high.

Lighting and Energy Efficiency

Natural lighting, LED fixtures, and smart energy systems reduce operating costs. Over time, energy-efficient design can save tens of thousands annually.

Safety and Compliance in Warehouse Construction

Building Codes and Regulations

Compliance isn’t optional. Warehouse construction must meet local building codes, fire safety standards, and occupational safety regulations. Failing inspections can halt operations entirely.

Fire Protection Systems

Sprinkler systems, fire-resistant materials, and proper aisle spacing are critical. In reality, insurers often dictate fire safety features as much as regulators do.

Sustainable and Green Warehouse Construction

Sustainability isn’t just a buzzword anymore. Green warehouse construction reduces operating costs and improves brand reputation. Common features include:

-

Solar panels

-

Rainwater harvesting

-

Energy-efficient HVAC systems

-

Recycled construction materials

That said, many governments now offer tax incentives for sustainable industrial buildings.

Technology Integration During Construction

Automation Readiness

Even if automation isn’t installed immediately, warehouse construction should anticipate it. Reinforced floors, power access, and data infrastructure make future upgrades smoother.

Smart Building Systems

Sensors for temperature, humidity, and energy usage improve operational control. In reality, these systems turn warehouses into data-driven assets rather than static buildings.

Choosing the Right Warehouse Construction Partner

Not all contractors understand industrial projects. Look for teams with:

-

Proven warehouse construction portfolios

-

Knowledge of logistics operations

-

Transparent cost estimates

-

Strong safety records

A cheaper bid often hides expensive change orders later.

Common Mistakes in Warehouse Construction

Even experienced developers make avoidable mistakes:

-

Underestimating future growth

-

Ignoring employee workflow

-

Choosing materials based only on price

-

Rushing the design phase

However, most issues trace back to poor planning rather than execution.

Warehouse Construction and Real Estate Value

A well-built warehouse isn’t just an operational asset—it’s a financial one. High-quality warehouse construction increases property value, attracts premium tenants, and improves resale potential. Investors increasingly view modern warehouses as long-term income generators.

Real-Life Example: Scaling a Distribution Center

A mid-sized retailer expanded its warehouse from 80,000 to 140,000 square feet using phased warehouse construction. By planning expansion joints and utility corridors early, the company avoided operational shutdowns and saved nearly 18% compared to relocating entirely. That kind of foresight separates good projects from great ones.

Warehouse Construction

Global supply chain disruptions have reshaped industrial real estate. Flexible, scalable warehouse construction now matters more than ever. Facilities designed with adaptability in mind weather market shifts far better than rigid, outdated buildings.

Cost Control Strategies That Actually Work

Effective warehouse construction budgeting includes:

-

Early contractor involvement

-

Value engineering without sacrificing quality

-

Fixed-price contracts where possible

-

Realistic contingency planning

On the other hand, unrealistic cost-cutting often leads to delays and rework.

Materials That Define Modern Warehouses

Flooring Systems

Warehouse floors endure constant abuse. High-strength concrete with proper joint spacing prevents cracking and supports heavy machinery.

Roofing and Insulation

Insulated roofing systems stabilize indoor temperatures and reduce energy costs. In reality, poor insulation quietly inflates monthly utility bills.

Workforce Comfort and Productivity

Happy workers are productive workers. Modern warehouse construction increasingly considers:

-

Ventilation and air quality

-

Noise reduction

-

Break areas and restrooms

That said, these features also help with employee retention in competitive labor markets.

FAQ Section

Frequently Asked Questions

What is the average cost of warehouse construction?

Costs typically range from $50 to $150 per square foot depending on size, materials, and technology requirements.

How long does warehouse construction usually take?

Most projects take between 8 and 18 months from planning to completion.

Is steel or concrete better for warehouse construction?

Steel is faster and flexible, while concrete offers superior durability and load capacity. The best choice depends on usage.

Can warehouses be expanded later?

Yes, if expansion is planned during initial warehouse construction through structural and site design.

Do warehouses require special permits?

Yes, zoning, environmental, and building permits are mandatory and vary by location.

How important is location in warehouse construction?

Location directly affects logistics costs, delivery times, and long-term profitability.

Are sustainable warehouses more expensive?

Initial costs may be higher, but long-term savings and incentives often offset the difference.

What ceiling height is ideal for a modern warehouse?

Clear heights of 28–40 feet are common for efficient vertical storage.

How does automation affect warehouse construction design?

Automation requires reinforced floors, precise layouts, and advanced electrical systems.

Conclusion

Warehouse construction sits at the crossroads of real estate, logistics, and long-term strategy. When done right, it supports growth, efficiency, and resilience for decades. When rushed or underplanned, it becomes a costly bottleneck.

That said, successful projects share one trait: thoughtful decisions made early. From site selection to structural design, every choice shapes how the warehouse performs long after construction ends.

Whether you’re building your first facility or scaling an existing network, treating warehouse construction as a strategic investment—not just a building project—makes all the difference.